In 2019, Provectus Environmental Products introduced the North American remediation market to the Provect-EBR® (US patent 9,975,156 B2) in situ generator of Reactive Oxidant Species. This was made possible through an exclusive agreement with Provectus and E. Elgressy LTD (Israel) to give exclusive license in the US and several other countries to Provectus. To improve operational and field implementation understanding, a week-long training session in early 2020 was held in Israel for the companies that are involved in the deployment of this technology both in the US and Europe. These partner companies include, but are not limited to, Field Data Solutions, Key Environmental, Sensatec GmbH, and BAW S.r.l.

EBR reactor in a demonstration tank showing the evolution of oxygen.

This training allowed for a detailed review of the manufacturing process and the key components involved in bringing this technology to the field. The group was educated on the design and construction of the EBR® reactor, the air introduction system, the EBR® control panel, and the firmware that operates the entire system. These training sessions provided a deeper understanding of the exacting tolerances of the components and the cutting edge controller system that allows this technology to generate the most Reactive Oxidant Species, such as the hydroxyl radical, superoxide radical, hydroperoxyl radical, and potentially ferrates without ever injecting any liquid oxidant solution into the subsurface.

EBR reactor and iron electrode during inspection and cleaning operation.

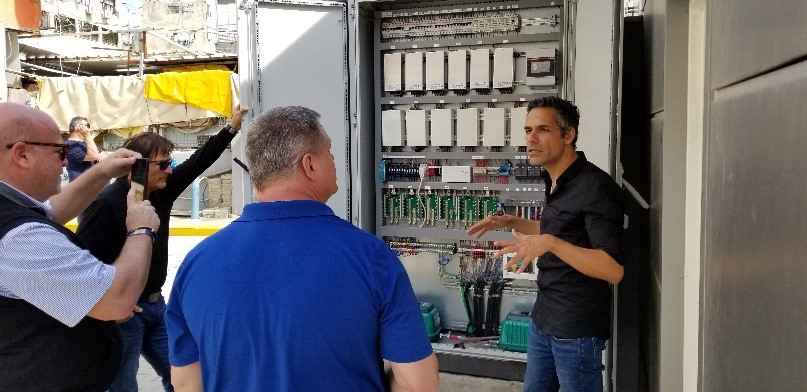

The host personnel from E. Elgressy LTD provided a personal on-site review of three active treatment sites, two of which are current case study locations. This hands-on experience allowed the teams to review actual installations and gain a better understanding of how this technology is implemented in real-world, active applications. The Elgressy team members reviewed operation of the system control panel and the expected routine maintenance to all components, including the EBR® reactor and the iron electrode. They were able to clearly show how the technology operates in a manner that is entirely non-disruptive to commercial active fueling stations. The periodic maintenance of the system did not require an operational shutdown, and there was no loss of treatment time during inspections and cleaning operations.

Team members discussing EBR reactor placement locations at Sonol Kakirion site in Haifa.

The training session allowed our team to have detailed discussions with Elie and Gil Elgressy, who designed and engineered the technology. It was a fantastic opportunity to have both theoretical and practical dialog regarding some topics that are high-level foundational thermodynamics to the true boots on the ground type installation and application scenarios. Our teams, both here in the US as well as Europe, continue to discuss and review potential application sites. We look forward to the time, in the near future, when our ability to travel and meet with our clients’ returns and be able to collaborate on field-scale Provect-EBR applications.

LEARN MORE | VIEW PRESENTATION | VIEW VIDEO SIMULATION

E. Elgressy Ltd. is a leading manufacturer of Electrochemical systems: Chemical free technologies at the forefront of technological innovation, research and development. Elgressy systems provide enhanced water treatment, Groundwater and soil remediation without using chemical products that are reliable and efficient. Low operation and maintenance costs. Reduced water consumption. Recyclable wastewater.