In Situ Chemical Oxidation + Enhanced Bioremediation for Contaminant Mass Destruction

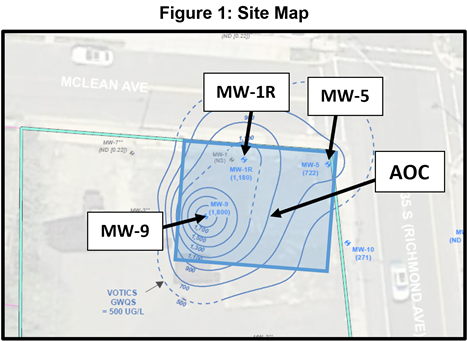

A former gas station located in Point Pleasant Beach, New Jersey was impacted with petroleum hydrocarbons due to leaks from underground storage tanks. The primary contaminants of interest (COIs) at the site were benzene, toluene, ethylbenzene, xylene (BTEX), trimethylbenzenes, and tentatively identified compounds (TICs) The area of concern (AOC) was approx. 2,600 sq ft with a target vertical interval from 7 to 11 feet below ground surface (ft bgs). The geology at the site is primarily a fine to medium grained sand with groundwater being encountered from 7 to 9 ft bgs. Provect-OX2™ was applied in situ to address the residual sorbed and dissolved phase petroleum hydrocarbon contaminant mass. Three primary monitoring wells were impacted within this AOC, including MW-1R, MW-5, and MW-9.

The remedial scope of work was developed by MidAtlantic Engineering Partners, LLC. and Provectus Environmental Products, Inc. (Provectus), which included the application of 7,550 lbs of Provect-OX2™ to the targeted AOC (Figure 1). Provect-OX2™ is a dual-functioning reagent blend that combines in situ chemical oxidation (ISCO) plus enhanced bioremediation (US Patent 9,126,245; patents pending). Provect-OX2™ rapidly oxidizes the organic contaminants present in soil and groundwater and provides long-term, sustained secondary bioremediation to manage residuals and prevent contaminant rebound. This is accomplished by using ferric iron (Fe III) as a safe and effective means of activating sodium and potassium persulfates, which quickly yields sulfate radicals (SO4-•) for chemical oxidation treatment. A pH buffer is also preblended with the Provect-OX2™ to offset any post-injection acidic pH conditions that are normally observed with traditional persulfate applications. The technology enhances subsequent utilization of sulfate and iron as terminal electron acceptors for facultative redox reactions to support secondary biodegradation of any residual contaminant mass.

Please contact Will Moody at (908) 581-6291 or via email for additional information regarding this project or our technologies. Furthermore, Troy Lizer can be reached at (330) 284-7428 or via email and Andy Lowy can be reached at (480) 670-7278 or via email.

Click Here for a site evaluation, conceptual remedial design, or material cost estimate with turn-key alternatives available upon request.